Northfield, Vermont

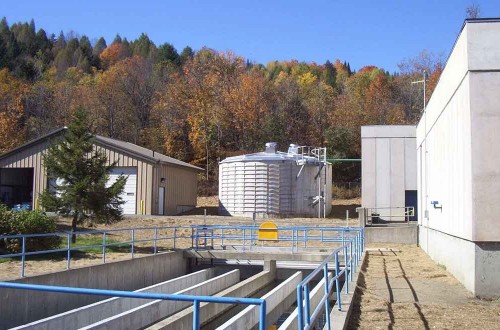

Comprehensive upgrade of 40-year-old wastewater treatment facility and process conversion from tricking filter to sequencing batch reactor (SBR) to comply with stringent phosphorous limitations. Replaced outdated headworks with fine screen and aerated grit chamber to improve removal of inorganics and FOG. Project included an innovative reuse of existing treatment process tank for post-SBR flow equalization, resulting in $200,000 savings.

Completed upgrade/replacement of biosolids processing including replacement of anaerobic digesters with aerated sludge storage, evaluation of alternative sludge dewatering technologies, new centrifuge and dewatered sludge screw conveyor, and efficient on-site storage/off-site hauling. Eliminated public health/safety threat by converting from 1-ton gas chlorine to liquid chlorination/dechlorination system. Energy efficient design techniques included premium efficient motors, heat recovery system from blower room, innovative day-lighting in Control Building, and new SCADA system for improved on-site/off-site monitoring. The site was constrained by the railroad and the Dog River, requiring geotechnical measures to protect rails.

DuBois & King was the prime consultant and provided all the professional engineering services associated with this facility, including structural, civil, electrical, mechanical, and construction inspection and management. The project received an award for engineering excellence in the annual competition sponsored by the American Council of Engineering Companies, Vermont Section.